An Enthusiast’s Guide to GPU, CPU & RAM Cooling

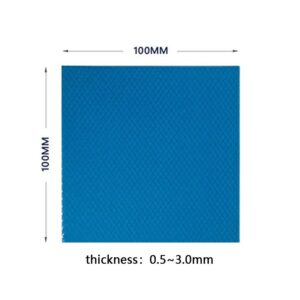

If you’re an avid PC builder and overclocking enthusiast, you know that proper thermal pad selection is instrumental in keeping your components cool. This comprehensive guide will equip you with everything you need to know about picking ideal thermal pad thicknesses.

Whether you’re cooling a hot-running graphics card, an unlocked CPU, or even upgrading laptop cooling – properly sized thermal pads enhance heat transfer from chips to heatsinks. Let’s dig in.

What Are Thermal Pads and Why Do They Matter?

Thermal pads are a thermal interface material (TIM) used to conduct heat away from electronics efficiently. They fill microscopic air pockets between hot components and heatsinks/cold plates, aiding thermal transfer where solid metal-to-metal contact isn’t possible.

Getting pad thickness and softness right directly impacts cooling performance. Thinner pads make better contact on flatter surfaces, while soft, squishy pads conform to uneven spots.

We’ll cover optimal thermal pad guidelines by use case, plus stacking methods for custom applications. Let’s start with demanding GPU cooling needs…

Graphics Card & GPU Cooling Recommendations

Modern GPUs produce extreme heat densities needing robust thermal solutions. Here are common graphics card thermal pad applications:

Modern GPUs produce extreme heat densities needing robust thermal solutions. Here are common graphics card thermal pad applications:

GPU Core & Die – Thermal paste is recommended instead for aftermarket cooling for die contact and pads surrounding the GPU.

VRAM Chips & Voltage Regulators – 1-1.5mm soft pads work best on these hot spots.

Backplates – At present, 0.5-1mm pads transfer heat.

Use Gelid Extreme 1mm or 1.5mm on GPU cores and VRAM areas needing significant cooling. Their softness conforms well to microscopic surface inconsistencies while avoiding pump out.

What about the ever-hotter high-core count CPUs?

CPU Cooling Pad Tips

While powerful CPUs require beefy cooling, their relatively small size allows thinner, effective pads:

- Between IHS and Heatsink: 0.5-1mm pads are commonly used here.

- Direct Die Cooling: When delidding, use ~0.5mm soft pads for best die contact.

- Larger HEDT CPUs may need 1-1.5mm pads for the increased heat output.

Generally, use Gelid Extreme 0.5mm or 1mm pads when delidding CPUs for optimal die contact area. The soft silicone compressibility helps greatly over hard stock pads.

Rest of System Recommendations

Other components like RAM, chipsets, and M.2 SSDs produce lower thermal densities than hot GPUs and CPUs. Typical applications:

- Bare RAM Chips: Gelid Extreme 0.3mm recommended.

- RAM/VRM Heatsinks: 0.5mm pads often used here.

- M.2 SSD Cooling: 1-1.5mm pads covering the controller and NAND work well.

The key is going as thin as possible while maintaining full contact over dies and hot spots for heat conduction to available cooling structures.

What Impacts Effective Thermal Pad Thickness?

Several variables influence the thickness needed for optimal cooling performance from thermal pads:

- Application – The type of component being cooled determines thermal load and contact area. A high-TDP CPU needs more cooling than low-power RAM chips.

- Surface Smoothness – Flatter, more uniform surfaces allow thinner pads to make consistent contact. Rough or wavy surfaces require thicker pads to conform.

- Pressure/Mounting Force – More mounting pressure lets thinner pads sufficiently fill gaps. Insufficient pressure demands thicker pads.

- Size/Weight – Larger, heavier components require thicker pads to displace air pockets. Low-profile components can use thinner pads.

So, in selecting thickness, you must consider the component, surface characteristics, and cooler mount.

Frequently Asked Enthusiast Questions

Now that we’ve covered component-specific guidelines, let’s answer some commonly asked thermal pad questions:

Q: How do I know when to replace worn thermal pads?

Visually inspect pads periodically for drying, cracking or lack of compression. Temperature deltas between cores/components exceeding 10°C indicate poor contact requiring pad replacement in most cases.

Q: Can I stack multiple thin thermal pads to achieve the desired thicknesses?

Absolutely. Stacking thin pads allows for effective customization of thicknesses when repasting components. Make sure to make a complete compressional contact area when mounting cooling solutions to avoid hot spots. Monitoring temperatures confirms pad stack effectiveness.

Q: What size thermal pads should I keep handy for PC projects?

Based on the above guidelines, having a supply of 0.5mm, 1mm and 1.5mm thickness thermal pads from quality brands like Gelid Solutions allows for effectively cooling all standard PC components as modding/upgrade needs arise.

Wrapping Up: Get Properly Sized Thermal Pads

We hope this enthusiast’s guide gives you confidence in selecting the right thermal pad thicknesses for upgrading GPUs, CPUs, laptops, consoles, and other electronics cooling needs.

While overlooked, quality thermal pads are crucial for heat transfer from critical components to heatsinks and cold plates. Following basic thickness guidelines by component and manufacturer specifications dials in cooling protection.

Combine properly sized thermal pads with top-shelf pastes, and you’re armed with the ultimate cooling toolkit for all your PC-building projects and passion.